#overcurrent relay

Explore tagged Tumblr posts

Text

motor protection relay | EOCR 3DM2 | schneider make | electronics motor...

youtube

Schneider EOCR 3DM2 Motor protection relay.

#motor protection relay#overcurrent relay#induction motor#jam protection#stall protection#earth fault protection#phase loss protection#unbalance protection#motor protection#Youtube

1 note

·

View note

Text

Industrial Overload Relays Market Industry Analysis Outlook by 2032

Market Overview:

Intrinsic safety modules are crucial components used in hazardous environments to ensure the safe operation of electronic equipment. These modules are designed to limit electrical energy and prevent the generation of sparks or excessive heat that could ignite flammable gases, vapors, or dust present in the surrounding atmosphere. By employing intrinsic safety modules, industries can reduce the risk of explosions and fires in potentially explosive atmospheres.

Intrinsic safety is a widely adopted protection technique in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, chemicals, and others where flammable substances are present. These modules are typically used with sensors, transmitters, and other electronic devices that need to operate in hazardous locations.

The Global Intrinsic Safety Modules Market size is projected to grow from $2.7 billion in 2021 to a billion by 2028, at a CAGR of 7% 2023-2031.

Industrial Overload Relays: Overview Industrial overload relays are electrical devices used to protect motors and other electrical equipment from damage due to overcurrent conditions. They are an essential component of motor control systems in industrial settings. These relays monitor the current flowing through a motor and can trip the circuit if the current exceeds a predefined threshold, thus preventing overheating and potential damage.

Industry Analysis and Trends:

Industrial Automation: The increasing adoption of industrial automation across various sectors has driven the demand for overload relays. Automation requires efficient motor protection to ensure smooth operation and prevent downtime.

Energy Efficiency: There is a growing emphasis on energy efficiency and reducing operational costs. Modern overload relays often come with features that enable energy monitoring and optimization.

Smart Technologies: The integration of smart technologies, such as IoT and connectivity, into industrial equipment has led to the development of smart overload relays. These relays can provide real-time data, remote monitoring, and predictive maintenance insights.

Safety Regulations: Stringent safety regulations and standards in industrial environments have led to the increased adoption of protective devices like overload relays. Compliance with these regulations is crucial for safe operations.

Miniaturization and Integration: The trend toward miniaturization and integration has led to the development of compact and multifunctional overload relay solutions, saving space and enhancing functionality.

Customization and Flexibility: Industries often have specific requirements for their motor protection needs. Manufacturers are focusing on offering customizable overload relay solutions to cater to various applications.

Global Industrial Growth: As industries continue to grow worldwide, the demand for machinery and equipment, including motors and overload relays, also increases.

Demand and Scope:

The demand for industrial overload relays is closely tied to the overall industrial growth, especially in sectors like manufacturing, oil and gas, utilities, mining, and more. As these industries expand, the need for reliable motor protection solutions becomes more critical. Moreover, the increasing adoption of automation and the integration of advanced technologies further contribute to the demand for modern overload relays.

The scope of the industrial overload relays market extends across various industries and applications, including conveyor systems, pumps, fans, compressors, HVAC systems, and more. As technologies evolve, the scope of overload relays may expand to include smarter and more advanced features, addressing emerging challenges in motor protection and predictive maintenance.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/intrinsic-safety-modules-market/13068/

Market Segmentations:

Global Intrinsic Safety Modules Market: By Company • Eaton • Rockwell Automation • Schneider Electric • Siemens • ABB • Pepperl+ Fuchs • OMEGA • Rotork • IMI Sensors • Extronics Global Intrinsic Safety Modules Market: By Type • Zener Barriers • Isolator Barriers • Converter Barriers Global Intrinsic Safety Modules Market: By Application • Oil and Gas • Mining • Power • Chemicals and Petrochemicals Global Intrinsic Safety Modules Market: Regional Analysis The regional analysis of the global Intrinsic Safety Modules market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Intrinsic Safety Modules market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Intrinsic Safety Modules in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Intrinsic Safety Modules in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Intrinsic Safety Modules in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Intrinsic Safety Modules in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/intrinsic-safety-modules-market/13068/?license=single

Reasons to Purchase Intrinsic Safety Modules Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Industrial Overload Relays#Motor Protection#Overcurrent Protection#Industrial Automation#Energy Efficiency#Smart Technologies#IoT Integration#Predictive Maintenance#Safety Regulations#Miniaturization#Customizable Solutions#Global Industrial Growth#Manufacturing#Oil and Gas#Utilities#Mining#Conveyor Systems#Pumps#Fans#Compressors#HVAC Systems#Market Trends#Demand Analysis#Industry Insights#Industrial Equipment#Motor Control#Electrical Protection.

0 notes

Text

Common Electrical Issues That a High-Quality Current Transformer Can Prevent

In today’s fast-paced industrial world, electrical reliability is more crucial than ever. A small error in current measurement can lead to serious system failures, downtime, and costly repairs. This is where high-quality current transformers (CTs) make a huge difference. But what exactly can a superior CT prevent? Let’s dive in.

What Is a Current Transformer?

A current transformer (CT) is an essential device used to measure alternating current (AC) by producing a scaled-down, manageable current for meters, relays, and other instruments. It enables safe monitoring and accurate metering in high-voltage environments, protecting both equipment and personnel.

Common Electrical Problems a High-Quality CT Can Prevent

1. Overloading and Equipment Failure

Problem: Without accurate current measurement, systems can easily become overloaded, causing motors, transformers, and cables to overheat.

How a CT Helps: A precision CT ensures real-time, reliable current monitoring. It detects overcurrent conditions immediately, allowing protective relays to trip and prevent expensive equipment damage.

2. Inaccurate Energy Billing

Problem: Incorrect current readings can lead to wrong billing, causing businesses to either overpay for energy or face disputes with utilities.

How a CT Helps: High-accuracy CTs provide precise energy data for billing and cost allocation, especially critical in commercial complexes, factories, and power plants.

3. Protection Relay Malfunction

Problem: If a CT delivers incorrect signals, protection relays may not operate during faults, leading to extended damage and system blackouts.

How a CT Helps: Reliable CTs ensure protection relays receive the correct fault current levels, enabling fast and accurate circuit isolation.

4. Short Circuits Going Undetected

Problem: A minor fault can escalate into a full-blown short circuit if the protection system doesn’t detect it early.

How a CT Helps: Quality CTs capture even small fault currents, triggering alarms or shutdowns before damage spirals out of control.

5. Phase Imbalance Issues

Problem: Imbalanced phases cause excessive heating, motor inefficiency, and damage to sensitive equipment.

How a CT Helps: High-precision CTs monitor each phase accurately, enabling detection of phase unbalance conditions early and preventing system inefficiencies.

6. Harmonic Distortions and Power Quality Problems

Problem: Harmonic distortions interfere with the performance of sensitive equipment and reduce the overall power quality.

How a CT Helps: Specialized CTs can detect abnormal waveform distortions, enabling corrective action through harmonic filtering or load balancing.

Why Invest in a High-Quality Current Transformer?

Accuracy: Achieve metering-class precision essential for both billing and protection. Durability: Longer lifespan even in harsh industrial environments. Safety: Better insulation, thermal stability, and overload capacity. Compliance: Meets international standards like IEC and ANSI.

How Enza Electric Ensures CT Excellence

At Enza Electric, we specialize in manufacturing current transformers built with precision, reliability, and global standards compliance. Whether you need CTs for commercial metering, industrial protection, or utility-scale power distribution, our solutions guarantee unmatched performance.

Customizable options for various ratings High dielectric strength for safety Long service life even in extreme conditions

Explore our Current Transformer Range

Final Thoughts

A high-quality current transformer isn’t just a tool — it’s a first line of defense for your electrical system. Investing in precision-engineered CTs prevents common electrical issues, boosts system longevity, ensures accurate billing, and improves overall operational safety.

If you’re serious about protecting your infrastructure and optimizing performance, choosing Enza Electric’s current transformers is a smart move.

9 notes

·

View notes

Text

Understanding the Role of Busbars, Circuit Breakers, and Relays in Switchgear

In the world of electrical distribution and control systems, switchgear plays a pivotal role in managing, protecting, and isolating electrical circuits and equipment. Within a switchgear assembly, components like busbars, circuit breakers, and relays are essential for ensuring efficient operation and maximum safety. Understanding the role of each of these components can help professionals and businesses make better decisions when designing or upgrading their electrical systems.

What Is Switchgear?

Switchgear is a general term that encompasses a wide range of electrical disconnect switches, fuses, circuit breakers, and associated equipment used to control, protect, and isolate electrical equipment. These systems are critical for both high-voltage and low-voltage applications and are commonly found in industrial plants, commercial buildings, power plants, and substations.

1. Busbars: The Power Distribution Backbone

Busbars are metallic strips or bars — typically made of copper or aluminum — that conduct electricity within a switchgear or distribution board. Their main function is to distribute electrical power to multiple circuits from a single input source.

Key Functions:

· Efficient Power Distribution: Busbars act as a central hub for distributing power to various outgoing circuits.

· Compact Design: Helps in reducing the overall footprint of the switchgear.

· Heat Dissipation: Designed to handle high currents while minimizing heat build-up.

Applications:

· Power distribution panels

· Switchboards and MCCs (Motor Control Centers)

· Panelboards and switchgear cubicles

2. Circuit Breakers: Protection from Overcurrent

Circuit breakers are automatic electrical switches designed to protect electrical circuits from damage due to overcurrent or short circuits. Unlike fuses, circuit breakers can be reset manually or automatically after tripping.

Key Functions:

· Fault Interruption: Instantly disconnects the circuit during faults to prevent damage or fire.

· Manual Switching: Can be used to manually turn circuits on or off during maintenance.

· Safety Compliance: Ensures that systems meet international safety standards (IEC, ANSI, etc.)

Types of Circuit Breakers:

· MCB (Miniature Circuit Breaker): Used for low-power applications

· MCCB (Molded Case Circuit Breaker): Handles higher loads than MCBs

· ACB (Air Circuit Breaker): Used for high-current circuits in industrial settings

3. Relays: The Sensing and Control Brains

Relays are electromechanical or solid-state devices that detect faults and send signals to circuit breakers or other control devices to disconnect the circuit. They are the “brains” behind the automatic protection mechanism of the switchgear.

Key Functions:

· Fault Detection: Monitors voltage, current, and other parameters to detect anomalies.

· Triggering Action: Sends signals to trip the circuit breaker when necessary.

· Automation and Coordination: Works in coordination with other protection devices to ensure selective tripping.

Types of Relays:

Overcurrent Relays

Differential Relays

Distance Relays

Earth Fault Relays

Why These Components Matter

Together, busbars, circuit breakers, and relays form the core of any switchgear system. When properly selected and configured:

· Downtime is minimized

· Equipment lifespan is extended

· Operational safety is enhanced

· Energy efficiency is improved

In an era where electrical reliability is non-negotiable, understanding these components isn’t just for engineers — it’s essential knowledge for decision-makers in any industry reliant on power.

Conclusion

Whether you’re designing a new electrical panel or upgrading an old one, choosing high-quality busbars, circuit breakers, and relays is critical to the safety and efficiency of your entire system. At AL Taqwa Oman, we specialize in premium-grade switchgear accessories that meet global standards and deliver unmatched performance.

Need help finding the right accessories for your panel? Contact our experts today and power your systems with confidence.

#electrical#electrical equipment#electrical supplies#switchgear#oman#electricity#busbar#relay#circuit breaker

8 notes

·

View notes

Text

Low Voltage Relays Explained: Types, Functions, and Applications

In the complex world of electrical systems, relays play a crucial role in ensuring safety, efficiency, and automation. Among these, low voltage relays stand out as versatile components that manage and protect circuits operating below 1000 volts. Whether in industrial automation, residential power distribution, or commercial infrastructure, these devices act as the nerve center of electrical control and protection.

In this comprehensive guide, we will break down what low voltage relays are, explore their types, explain their functions, and highlight their diverse applications across industries.

What Are Low Voltage Relays?

A low voltage relay is an electrically operated switch that uses a small control voltage (typically below 1000V AC or DC) to switch larger electrical loads on and off. These relays act as intermediaries between control circuits and power circuits, providing isolation, control, and protection.

Unlike manual switches, relays automate the process of circuit management, responding to electrical signals, fault conditions, or system commands without human intervention.

Types of Low Voltage Relays

Low voltage relays come in several forms, each tailored to specific tasks within an electrical system. Here are the main types:

1. Electromechanical Relays (EMRs)

· Use a coil and a movable armature to open or close contacts.

· Provide physical isolation between input and output.

· Common in traditional control panels and basic automation.

2. Solid-State Relays (SSRs)

· Use semiconductors (like thyristors or triacs) instead of mechanical contacts.

· Offer silent operation, faster switching, and longer lifespan.

· Ideal for high-speed applications and environments requiring low maintenance.

3. Overload Relays

· Specifically designed to protect motors and equipment from sustained overcurrent.

· Available as thermal overload relays (using bimetallic strips) or electronic overload relays (using sensors and processors).

4. Time Delay Relays

Provide a deliberate time lag between the relay receiving a signal and switching.

Used in motor control circuits, lighting systems, and sequential operations.

5. Overcurrent and Short-Circuit Relays

· Detect and react to current exceeding preset thresholds.

· Essential for system protection against faults and overloads.

6. Voltage Monitoring Relays

· Monitor voltage levels and trip when voltages fall below or rise above safe limits.

· Protect sensitive devices from under voltage and overvoltage conditions.

Functions of Low Voltage Relays

Low voltage relays serve multiple vital functions in electrical systems:

1. Switching and Control

Relays control the opening and closing of power circuits in response to low voltage signals from controllers, timers, or sensors. This enables remote and automated control of large electrical loads.

2. Protection

Relays detect abnormal conditions like overloads, overcurrent, under voltage, and phase failures. When such conditions arise, they disconnect the affected circuit to prevent equipment damage or fire hazards.

3. Isolation

They electrically isolate control circuits (usually low voltage, low current) from power circuits (high voltage, high current), ensuring safety and reducing interference.

4. Signal Amplification

A small control signal (from a PLC, sensor, or microcontroller) can trigger a relay to switch much larger loads, effectively amplifying the control power.

5. Automation and Sequencing

In complex systems, relays help sequence operations by ensuring that processes occur in the correct order and at the right time intervals.

Applications of Low Voltage Relays

Low voltage relays are the backbone of automation and protection in various industries. Here are some key application areas:

Industrial Automation

· Control of motors, pumps, conveyor belts, and production lines.

· Use in programmable logic controllers (PLCs) and distributed control systems (DCS).

Power Distribution Systems

· Protect electrical panels from overload and short circuits.

· Monitor voltage and current levels in distribution boards.

Building Automation

· Lighting control systems.

· HVAC (heating, ventilation, and air conditioning) systems.

· Elevator and escalator controls.

Renewable Energy Systems

· Manage and protect solar inverters, battery banks, and wind turbines.

· Automatically disconnect faulty sections to prevent system-wide failures.

Data Centers and IT Infrastructure

· Ensure stable power supply to servers and networking equipment.

· Protect sensitive electronics from voltage fluctuations.

Transportation

· Railways, metros, and automotive applications for control and safety circuits.

Home Appliances

· Found in washing machines, microwave ovens, and HVAC units to automate functions and provide protection.

Advantages of Using Low Voltage Relays

· Enhanced Safety: Isolate control and power circuits, reducing electrical shock risks.

· Automation Ready: Easily integrated into automated systems for smarter operation.

· Cost-Effective Protection: Safeguard expensive equipment from damage due to electrical faults.

· Versatile: Available in many forms to suit different voltage levels, currents, and response times.

· Reduced Maintenance: Especially with solid-state relays, which have no moving parts.

Future Trends: Smart Relays and IoT Integration

As industries move toward smart grids and Industry 4.0, low voltage relays are also evolving:

· Digital relays offer programmable settings, self-testing, and event recording.

· IoT-enabled relays can send status updates and alerts to centralized monitoring systems.

· Energy-efficient designs reduce power consumption while providing reliable protection.

Conclusion

Low voltage relays are indispensable in modern electrical engineering, seamlessly combining protection, control, and automation. From safeguarding your home appliances to managing the power in a sprawling industrial plant, these devices ensure that electrical systems run smoothly and safely.

Understanding the different types, functions, and applications of low voltage relays empowers system designers, engineers, and even DIY enthusiasts to build safer and more efficient electrical setups.

As technology advances, the role of these small but mighty devices will only grow, driving the future of safe, smart, and automated power systems.

9 notes

·

View notes

Text

Low Voltage Switchgear for Commercial Buildings: Key Requirements, Standards, and Best Practices

In the construction and modernization of commercial buildings, low voltage switchgear plays a critical role in ensuring safe, reliable, and efficient power distribution. From office complexes and retail malls to hospitals and data centers, these buildings rely on robust electrical infrastructure — and low voltage switchgear is the backbone of that system.

Whether you’re an electrical panel manufacturer, a building contractor, or a facility manager, understanding the key requirements for selecting and integrating LV switchgear in commercial buildings is essential.

What Is Low Voltage Switchgear?

Low voltage switchgear is an assembly of electrical devices designed to control, protect, and isolate electrical circuits under 1,000V AC. It typically includes:

· Air Circuit Breakers (ACBs)

· Molded Case Circuit Breakers (MCCBs)

· Miniature Circuit Breakers (MCBs)

· Contactors and Relays

· Busbars

· Metering and Protection Devices

Why LV Switchgear Is Critical in Commercial Buildings

Commercial buildings demand:

· Continuous power availability

· High energy efficiency

· Electrical safety for occupants

· Scalability for future expansion

Low voltage switchgear delivers:

· Protection against overloads and short circuits

· Isolation for maintenance and fault conditions

· Load management for energy optimization

· Monitoring via smart metering and IoT integration

Key Requirements for LV Switchgear in Commercial Applications

Safety & Protection Standards

Must comply with IEC 61439 or UL 891 depending on the region

Must include overcurrent, short-circuit, and earth fault protection

Arc flash safety features (like arc fault containment) are crucial in populated buildings

2. Compact Footprint and Modular Design

Space is often limited in commercial utility rooms. LV switchgear should be:

Compact to fit tight electrical rooms

Modular for easy expansion as building loads increase

3. Smart Metering and Monitoring

Today’s commercial buildings demand energy-efficient and intelligent systems. Choose LV switchgear with:

Integrated smart meters

IoT-based energy monitoring

Remote control via BMS (Building Management Systems)

4. High Service Continuity (Form Segregation)

To ensure maintenance without full shutdowns, opt for:

Form 3b or Form 4b segregation

Withdrawable ACBs or MCCBs

Dual incomer and bus coupler arrangements for redundancy

5. Scalability and Flexibility

Commercial facilities evolve. Your switchgear must too:

Allow for load expansion

Be compatible with renewable sources (like solar panels)

Support future retrofits and upgrades

Standards to Follow

Ensure LV switchgear in commercial buildings is compliant with:

IEC 61439–1/2 — General and Power Switchgear Assemblies

UL 891 — US Standard for Dead-Front Switchboards

NEC (National Electrical Code) or local building codes

Also factor in:

Ingress Protection (IP Ratings) — IP54/IP65 for dusty or humid environments

Short Circuit Withstand Ratings — Ensure it matches building fault levels

Best Practices for Installation in Commercial Building

Centralize the switchgear for easy maintenance and reduced cable runs

Provide ample ventilation or forced cooling

Use color-coded wiring for clear identification

Ensure emergency shutdown mechanisms are accessible

Document the system with single-line diagrams and load calculations

Applications in Commercial Buildings

Office Buildings: Smart load shedding and energy metering

Hospitals: Redundant systems for life safety

Data Centers: N+1 configurations and continuous monitoring

Malls & Retail: Segmented load distribution for different zones

Hotels: Backup and emergency panel integration

Choosing the Right LV Switchgear Partner

Look for a supplier who provides

Customized switchgear assemblies

Fast lead times and local support

Engineering assistance for layout and specs

Pre-tested or type-tested assemblies

Future Trends in Commercial LV Switchgear

Digitization & predictive maintenance

Energy-efficient, low-loss designs

AI-assisted load forecasting

SF6-free eco-friendly designs

Need Help Choosing LV Switchgear for Your Next Commercial Project?

At Daleel Trading, we supply certified, compact, and smart low voltage switchgear solutions tailored for commercial buildings. Whether it’s a small retail site or a multi-floor office tower, we deliver performance, compliance, and reliability — on time.

👉 Contact us today for a quote, a technical consultation, or a custom panel solution.

8 notes

·

View notes

Text

Switchgear for Solar and Wind Projects in Bahrain: What You Need to Know

As Bahrain intensifies its commitment to renewable energy, solar and wind power projects are gaining momentum across the Kingdom. The nation’s Vision 2030 emphasizes sustainable growth, and this includes an ambitious target of generating 10% of electricity from renewable sources by 2035. As developers and investors gear up for this energy transition, one component plays a critical role in ensuring system safety, reliability, and efficiency — switchgear.

In this article, we explore why switchgear is crucial in solar and wind power systems, the specific requirements in Bahrain, and how to choose the right solution for your renewable energy project.

What is Switchgear and Why Does it Matter?

Switchgear is a general term covering a wide range of electrical devices used to isolate, protect, and control electrical circuits. It includes circuit breakers, fuses, relays, disconnectors, and load break switches.

In renewable energy systems, switchgear ensures:

· Safe disconnection of faulty or overloaded circuits

· Protection against overcurrent, short-circuit, and earth faults

· Efficient control and monitoring of power flow

· Coordination with grid and off-grid systems

Renewable Energy Growth in Bahrain

Bahrain’s sunny climate and strong coastal winds make it an ideal location for solar PV and wind power installations. Recent government initiatives — such as the Net Metering Scheme, Tendered Renewable Projects, and Green Building Regulations — are creating opportunities for both utility-scale and distributed renewable energy systems.

However, environmental factors such as high temperatures, humidity, and dust pose challenges for electrical equipment, particularly in outdoor solar and wind sites. This makes the right choice of switchgear even more important.

Key Switchgear Considerations for Solar Projects

In photovoltaic (PV) installations, switchgear must be compatible with DC (direct current) as well as AC (alternating current) systems. Here are specific points to consider:

1. DC Switchgear for PV Arrays

· DC Disconnectors: Isolate individual PV strings for maintenance or emergency shutdowns.

· DC Fuses and Circuit Breakers: Protect cables and components from over currents.

· String Combiner Boxes: Integrate multiple PV strings and incorporate protective devices.

2. AC Switchgear for Inverter Output

· Low-Voltage Circuit Breakers (AC): Used between inverters and transformers or grid connection points.

· Load Break Switches: Offer safe disconnection under load conditions.

· Metering and Monitoring Units: Allow real-time tracking of power output and faults.

3. Environmental Protection

· Use switchgear with IP65-rated enclosures to protect against dust and water ingress.

· UV-resistant materials are vital for long-term durability under the Bahraini sun.

Switchgear in Wind Energy Systems

Wind energy systems involve varying voltage levels and require robust protection due to fluctuating wind speeds and mechanical loading. Key switchgear elements include:

1. Medium Voltage Switchgear

· Used for interconnection between wind turbines and step-up transformers.

· SF6 or Vacuum Circuit Breakers: Provide arc quenching and insulation under high voltage.

2. High-Speed Protection

· Wind turbines are sensitive to voltage dips and transients. Fast-acting relays and breakers prevent equipment damage.

· Reactive power control and grid fault detection are integrated into switchgear assemblies.

3. Compact, Modular Designs

· Space constraints inside turbine towers or nacelles demand compact switchgear solutions with modular layouts.

Bahrain-Specific Compliance and Standards

To ensure your switchgear meets local utility and regulatory requirements, consider the following:

· EWA (Electricity & Water Authority) Requirements: All grid-connected systems must comply with EWA’s interconnection standards, including protection schemes and disconnection devices.

· IEC Standards: Switchgear must comply with relevant IEC 60947 (low-voltage switchgear) and IEC 62271 (high-voltage switchgear) guidelines.

· Thermal Rating and Ambient Temperature: Switchgear should be rated for continuous operation at temperatures up to 50°C, common in Bahraini summers.

Choosing the Right Switchgear Partner

A successful renewable energy project hinges on choosing a reliable switchgear partner. Look for:

· Local experience in Bahraini environmental and regulatory conditions

· Customizable solutions for both rooftop and utility-scale systems

· After-sales support including spares, maintenance, and system upgrades

· Smart switchgear with digital monitoring for preventive maintenance and remote control

Future Trends in Switchgear for Renewables

As solar and wind systems grow more advanced, so does switchgear technology. Key trends include:

· Digital Switchgear: Real-time monitoring, predictive maintenance, and IoT integration

· Arc-Resistant Designs: Enhanced safety for personnel in substations

· Eco-Friendly Alternatives to SF6: Adoption of green gases and air-insulated switchgear

· Hybrid AC/DC Systems: With growing battery storage and hybrid plants, switchgear must handle both current types seamlessly

Conclusion

Whether you’re planning a rooftop PV installation or a wind farm in Bahrain, your switchgear solution must be robust, compliant, and tailored to the region’s unique challenges. By choosing the right switchgear system, you ensure operational efficiency, regulatory compliance, and long-term safety.

If you’re looking for expert advice or need help selecting switchgear for your solar or wind project in Bahrain, our team is here to help. Contact us today for tailored solutions that power your progress sustainably.

#electrical engineers#electrical supplies#switchgear#electrical equipment#911 abc#bahrain25#arcane#artists on tumblr#batman#cats of tumblr

3 notes

·

View notes

Text

Why does my headlight fuse blow every time I turn the headlights on?

The following is an analysis of the causes and solutions for frequent blown headlight fuses, using a structured troubleshooting process:

1. Direct cause location Blown fuses indicate that the circuit is overloaded or short-circuited. Common fault points are as follows:

1. Bulb problem

Wrong wattage: The power of the replaced bulb (such as 100W) exceeds the original design (usually 55W-65W), and the current exceeds the fuse carrying capacity.

✅ Solution: Check the power marked on the bulb base and replace it with the original specifications.

Internal short circuit of the bulb: The filament touches the electrode after melting, causing a short circuit.

✅ Solution: Remove the bulb and test the resistance with a multimeter (normally it should be 0.5-2Ω).

2. Line short circuit

Line wear: The wiring harness rubs against the metal frame in the engine compartment, causing the insulation layer to be damaged (commonly seen at the corners of the firewall).

✅ Troubleshooting method: Visually inspect the outer sheath of the wiring harness, focusing on the rear of the headlights, the inside of the bumper and other areas prone to friction.

Modification interference: The wiring of the added daytime running lights, spotlights, etc. is wrong, and the positive pole is directly grounded.

✅ Verification method: Disconnect all modified equipment and test whether the original circuit is normal.

3. Connector failure

Socket corrosion: The headlight plug is oxidized by water, and conductive salt crystals are formed between the metal contacts (more frequent failures on rainy days).

✅ Treatment: Spray the plug with electronic cleaner, sandpaper the contacts, and apply dielectric grease (insulating sealing grease).

Pin misalignment: The internal pins of the plug are bent, causing a short circuit (common in aftermarket headlight assemblies).

✅ Inspection: Unplug the plug and observe whether the pins are arranged neatly.

4. Relay/switch failure

Relay adhesion: The headlight relay contacts are melted, and a direct short circuit is formed when power is turned on.

✅ Test: Unplug the relay and short-circuit pins 30 and 87 with a jumper. If the fuse does not burn, the relay is normal.

Carbonization of the combination switch: The oxidation of the internal contacts of the headlight switch causes a surge in resistance, and local overheating causes overcurrent.

✅ Verification: Use a multimeter to measure the resistance when the switch is turned on (should be <1Ω).

II. Systematic diagnostic process Steps Operation Tools/methods Expected results 1 Replace the original bulb Compare the power labels of the new and old bulbs Eliminate the overpower problem 2 Disconnect all modified circuits Restore the original wiring harness Eliminate interference from third-party equipment 3 Remove the headlight plug and measure the resistance of the positive pole of the socket to the ground Adjust the multimeter to the resistance range (negative pole grounded) Normally it should be ∞ (infinity), if it is 0Ω, the line is short-circuited 4 Check the wiring harness from the fuse box to the headlight Visually + flashlight to check whether there is skin breakage or melting marks Find physical damage points 5 Replace the relay test Same model relay replacement method Confirm whether the relay is faulty

III. Hidden risk warning

Sequelae of flooding: The copper wire inside the wiring harness of the wading vehicle is oxidized, and the leakage current increases in a humid environment.

✅ Countermeasures: Use compressed air to blow dry the plug and measure the insulation resistance of the wiring harness (should be >10MΩ).

Parallel load interference: The air conditioning fan and the audio amplifier share a poor grounding, causing the current to be discharged through the headlight circuit.

✅ Troubleshooting: Check whether the bolts of the grounding points of the entire vehicle are tight and free of rust.

Fourth, the ultimate solution If the above troubleshooting is fruitless, do the following:

Disassemble the headlight assembly: Check whether the internal components such as the reflector bowl and the adjustment motor are short-circuited (case: the seal of the adjustment motor of a German car failed and caused a short circuit).

Simulated load test: Connect a current clamp to the fuse position and capture the current peak at the moment of turning on the light (normal value: 55W bulb ≈ 4.6A×2).

Isolate the wiring harness in sections: Disconnect the wiring harness section by section starting from the fuse box and lock the short-circuit section.

Repair cost reference Fault point Repair plan Cost (estimate) Wrong bulb power Replace original bulb ¥50-200 Wire harness broken and shorted Welding + heat shrink tube insulation ¥100-300 Corrosion of headlight plug Replace plug assembly ¥80-150 Damaged combination switch Replace switch assembly ¥300-800

Notes:

Do not use iron wire/copper wire instead of fuse, which may cause fire.

It is recommended to use slow-blow fuses (such as J-case type) to deal with instantaneous surge current.

If it is difficult to troubleshoot by yourself, it is recommended to use a diagnostic instrument to read the BCM (body control module) fault code to locate the specific circuit abnormality.

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car light#car culture#classic cars#car#race cars#cars#coupe#suv#chevrolet#convertible#supercar#headlight#headlight bulb#headlight restoration#headlamp#car lamp#lamp#fuse blow#fuse#fused zamasu

2 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

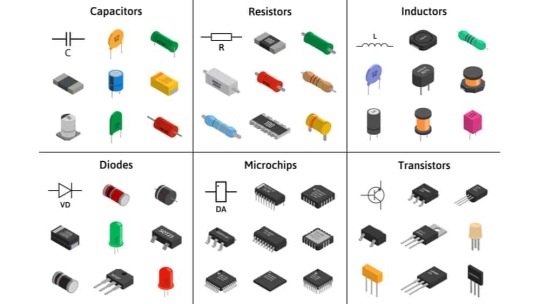

Electronics Components and Uses:

Here is a list of common electronics components and their uses:

Resistor:

Use: Limits or controls the flow of electric current in a circuit.

Capacitor:

Use: Stores and releases electrical energy; used for filtering, timing, and coupling in circuits.

Inductor:

Use: Stores energy in a magnetic field when current flows through it; used in filters, transformers, and oscillators.

Diode:

Use: Allows current to flow in one direction only; used for rectification, signal demodulation, and protection.

Transistor:

Use: Amplifies and switches electronic signals; fundamental building block of electronic circuits.

Integrated Circuit (IC):

Use: Contains multiple electronic components (transistors, resistors, capacitors) on a single chip; used for various functions like amplification, processing, and control.

Resistor Network:

Use: A combination of resistors in a single package; used in applications where multiple resistors are needed.

Potentiometer:

Use: Variable resistor that can be adjusted to control voltage in a circuit; used for volume controls, dimmer switches, etc.

Varistor:

Use: Protects electronic circuits from excessive voltage by acting as a voltage-dependent resistor.

Light-Emitting Diode (LED):

Use: Emits light when current flows through it; used for indicator lights, displays, and lighting.

Photodiode:

Use: Converts light into an electric current; used in light sensors and communication systems.

Zener Diode:

Use: Acts as a voltage regulator by maintaining a constant voltage across its terminals.

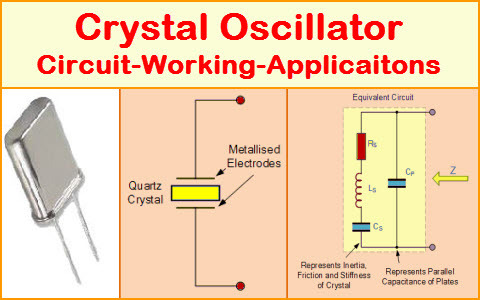

Crystal Oscillator:

Use: Generates a stable and precise frequency; used in clocks, microcontrollers, and communication devices.

Transformer:

Use: Transfers electrical energy between two or more coils through electromagnetic induction; used for voltage regulation and power distribution.

Capacitive Touch Sensor:

Use: Detects touch or proximity by changes in capacitance; used in touchscreens and proximity sensing applications.

Voltage Regulator:

Use: Maintains a constant output voltage regardless of changes in input voltage or load; used for stable power supply.

Relay:

Use: Electromagnetic switch that controls the flow of current in a circuit; used for remote switching and automation.

Fuse:

Use: Protects electronic circuits by breaking the circuit when current exceeds a certain value; prevents damage from overcurrent.

Thermistor:

Use: Resistor whose resistance changes with temperature; used for temperature sensing and compensation.

Microcontroller/Microprocessor:

Use: Processes and controls electronic signals; the brain of many electronic devices and systems.

fig:google-electronics

fig:google-electronics

fig:Crystal-Oscillator

This list covers some of the basic electronic components, and there are many more specialized components used for specific applications within the field of electronics.

#electronic#electricity#electric vehicles#electric cars#engineering#semiconductors#wireless#cables#electronics#smartphone#hardware

4 notes

·

View notes

Text

0 notes

Text

What Makes Siemens Load Breakers the Ideal Choice for Industrial Safety

In today’s highly demanding industrial environment, electrical safety and efficiency aren’t just important—they’re non-negotiable. Whether you're running a manufacturing plant, a processing unit, or a commercial facility, the equipment you choose plays a crucial role in the stability and security of your power systems. Among all electrical protection solutions available today, load breaker Siemens products stand out for their precision engineering, long-term durability, and proven safety record. For industries located in regions like Bhavnagar, where power reliability is critical to operations, having access to premium solutions such as load breaker Siemens in Bhavnagar ensures the kind of safety and control that businesses need to thrive. To satisfy the various demands of Indian enterprises, Darshil Enterprise, a reputable brand in industrial electrical equipment, provides an extensive selection of Siemens electrical solutions.

What Is a Load Breaker and Why Siemens?

A load breaker is an essential part of an industrial electrical system, designed to isolate, switch, and protect circuits during normal operations or emergencies. Siemens, a global leader in electrical technology, offers a complete line of industrial load breakers tailored to meet modern industry standards.

Siemens power breakers and circuit breakers stand out for their superior build quality and ingenious design. These components ensure faultless interruption of electric current, enhanced arc quenching, and reliable protection against overloads and short circuits.

Durability Meets Innovation

Heavy-duty load breakers are expected to function under tough conditions—extreme heat, voltage fluctuations, heavy loads, and constant switching. Siemens doesn’t just meet these demands—it exceeds them. Every load breaker Siemens product is rigorously tested to perform reliably in the most challenging environments.

Key Siemens electrical products available through Darshil Enterprise include:

Air Circuit Breakers

Moulded Case Circuit Breakers

Load Break Switches

Fuses

Overload Relays

Contactors

Microprocessor-Based O/L Relays

Each of these components is designed to work in harmony with Siemens switchgear to create a powerful and reliable protection network.

Siemens Breaker Safety and System Compatibility

Another reason for Siemens' popularity is system compatibility. Siemens breakers integrate effortlessly into existing and new electrical installations, offering both manual and automated control options. This promises efficient energy distribution and best operational uptime.

Whether it's a Siemens breaker safety concern or system flexibility, industries trust Siemens for one main reason: it works flawlessly when it matters most.

Applications Across Industries

From power plants and oil refineries to pharmaceutical units and textile factories, Siemens electrical protection systems are widely used for:

Equipment protection

Load management

Emergency shutdowns

Fault isolation

Energy optimization

Choosing load breaker Siemens in Bhavnagar means aligning your facility with global standards while maintaining local support and availability through Darshil Enterprise.

More Than Just Breakers: Total Siemens Electrical Solutions

Siemens doesn't stop at breakers. Its product ecosystem includes:

Contactors for motor control

Overload relays to protect motors from overcurrent

Microprocessor-Based O/L Relays for advanced diagnostics

Siemens switchgear assemblies for complete load control

These solutions are designed for smart factories, green buildings, and mission-critical operations, helping companies adopt intelligent energy management systems while ensuring full-scale protection.

Why Buy from Darshil Enterprise?

Darshil Enterprise has built a strong reputation by delivering authentic Siemens electrical solutions to industries across Bhavnagar and Gujarat. Their team of experts provides end-to-end support, from choosing the right product to installation and after-sales service.

Whether you need a load break switch Siemens, a Siemens circuit breaker, or a moulded case circuit breaker, Darshil Enterprise ensures that you get genuine products, competitive prices, and expert advice.

Conclusion

Safety, efficiency, and system longevity should never be compromised when it comes to industrial operations. Choosing Siemens load breakers and electrical protection devices ensures your business is protected by some of the best engineering in the world.

From heavy-duty load breakers to smart switchgear, every Siemens product sold through Darshil Enterprise is a step toward a safer, more reliable industrial future. If you're looking to upgrade your facility's electrical safety with world-class solutions, Siemens and Darshil Enterprise are the partners you can trust.

Contact Darshil Enterprise Today! Call Now: +91 99987-13713 or Email: [email protected]. Make your operations safer, smarter, and more efficient—with Siemens and Darshil Enterprise.

#load breaker siemens in Bhavnagar#load breaker Siemens#Siemens circuit breaker#Siemens power breaker#industrial load breaker#Siemens electrical protection#heavy-duty load breaker

0 notes

Text

0 notes

Text

0 notes

Text

Protecting Your Electrical Systems: A Look into Al Taqwa’s Complete Range

In today’s fast-paced world, electrical systems power everything from homes and offices to factories and infrastructure. With increasing energy demands and the growing importance of uninterrupted power supply, having the right switchgear and protection systems is more important than ever. That’s where Al Taqwa United Enterprises LLC, one of Oman’s leading electrical suppliers, plays a crucial role.

In this blog, we’ll explore how Al Taqwa offers a complete range of electrical switchgear products that protect and power systems across the country — safely and efficiently.

Why Electrical Protection Is Critical

An electrical system without proper protection is like a car without brakes. From power surges to short circuits, the risks of equipment damage, data loss, and fire hazards are significant. High-quality electrical protection devices ensure:

· Safe power distribution

· Equipment longevity

· Compliance with safety standards

· Reduced downtime in case of faults

Al Taqwa addresses all of these needs with a comprehensive and reliable product portfolio.

Al Taqwa: A Trusted Name in Electrical Switchgear in Oman

Established in 20011, Al Taqwa United Enterprises LLC has grown into a respected electrical trading and switchgear assembly company in Oman, Qatar, the UAE, and India. Their focus on quality, innovation, and customer satisfaction makes them a preferred partner for engineers, contractors, and facility managers across sectors.

Complete Electrical Switchgear Range from Al Taqwa

Al Taqwa’s product line is designed to meet the needs of low-voltage electrical systems in residential, commercial, and industrial environments.

1. Electrical Panels and Distribution Boards

These serve as the central hub for electrical power distribution. Al Taqwa supplies and assembles:

· Main Distribution Boards (MDBs)

· Sub Main Distribution Boards (SMDBs)

· Final Distribution Boards (FDBs)

· Control Panels and Feeder Pillars

All panels are tailored to meet Omani electrical standards and international safety norms.

2. Circuit Protection Devices

The key to preventing electrical fires and damage is reliable overcurrent and earth fault protection. Al Taqwa offers:

· Miniature Circuit Breakers (MCBs)

· Molded Case Circuit Breakers (MCCBs)

· Residual Current Devices (RCDs)

· Earth Leakage Relays

These components ensure quick fault detection and automatic power cut-off during hazards.

3. Metering and Monitoring Devices

To optimize energy use and improve system performance, monitoring is essential. Al Taqwa provides:

· Analog and Digital Panel Meters

· Current Transformers (CTs)

· Voltage and Frequency Meters

· Energy Monitoring Units

These products give real-time data for smarter electrical management.

4. Electrical Accessories and Control Components

To support the full installation lifecycle, Al Taqwa stocks:

· Terminal blocks

· Cable ties and lugs

· Contactors and timers

· Rotary switches and power supplies

These ensure smooth installation, operation, and maintenance of electrical systems.

Top Electrical Brands Represented by Al Taqwa

Al Taqwa partners with internationally recognized electrical brands, including:

· Enza Electric — Quality switchgear products known across Europe and the Middle East

· Civaux Electric — Comprehensive panel systems and circuit protection components

· Stefan Electric — Trusted for metering solutions and industrial electrical accessories

· Salzer Electric — Renowned for rotary switches and control products

These collaborations ensure Al Taqwa can offer reliable, durable, and cost-effective solutions to its clients.

Beyond Products: Al Taqwa’s Expert Services

Al Taqwa goes beyond just supplying electrical components. Their team of experts offers:

Custom switchgear assembly tailored to project requirements

Site inspections and installation support

Annual maintenance contracts

Technical consultation and troubleshooting

This makes Al Taqwa a one-stop solution for all electrical needs in Oman.

Conclusion: Trust Al Taqwa for Complete Electrical Protection

When it comes to protecting your electrical systems, choosing a trusted provider like Al Taqwa ensures both peace of mind and long-term performance. From high-quality panels and circuit breakers to metering systems and expert service, Al Taqwa covers the full spectrum of electrical protection.

For engineers, project managers, or business owners looking to safeguard their infrastructure, Al Taqwa United Enterprises LLC stands out as the best source of electrical switchgear in Oman.

Explore More:

Visit https://altaqwaoman.com to view the full product catalog or request a quote tailored to your project needs.

#electrical#electrical equipment#electrical supplies#switchgear#oman#ElectricalSystems#ElectricalSafety#ElectricalSolutions#ElectricalProtection#SwitchgearSolutions#PowerDistribution#LowVoltageSystems#CircuitProtection#ElectricalPanels#ControlPanels

3 notes

·

View notes

Text

Which Challenges are in Generator Overcurrent Protection?

Although overcurrent protection is essential for the safety and longevity of generators, its implementation can be quite challenging due to various factors. These challenges arise from the complexity of the electrical system, the unique characteristics of generators, and the need for precise coordination between protective devices. Below are some of the key challenges in generator overcurrent protection:

1. Coordination with other protective devices Generators often operate in conjunction with a wide range of electrical equipment, including transformers, circuit breakers, and relays. The biggest challenge in overcurrent protection is ensuring proper coordination between the generator protection system and other equipment in the electrical system.

Protective devices must trip in a sequence that minimizes the impact on the overall system, ensuring that only the affected equipment is isolated while the rest of the system continues to operate. Improper coordination can cause unnecessary power outages or damage to other equipment.

2. Response to Fault Conditions Overcurrent protection must be responsive to a variety of fault conditions, including short circuits, overloads, and ground faults. These faults often have different characteristics, and the protection system needs to be designed to respond appropriately for each scenario.

The generator’s protection system may struggle to distinguish between temporary surges in current (e.g., motor start-up) and more serious, long-term overcurrent conditions that can cause damage.

3. Generator characteristics and load variations Generators can vary significantly in their performance and load types. Generators may experience load changes due to operational demands, including motor start-up surges or fluctuations in the types of connected loads.

Overcurrent protection settings that are too sensitive may trip for transient spikes caused by load changes, while settings that are too lenient may not protect the generator in the event of prolonged overload.

4. Fault Detection Time One of the primary challenges of overcurrent protection is to detect faults quickly while minimizing time delays to prevent damage to the generator and connected loads.

For short circuits, overcurrent protection must operate almost instantaneously to avoid catastrophic damage. However, for overloads, the protection system must allow the generator some time to clear the overload condition without triggering a trip unnecessarily.

5. Ground Fault Protection Ground faults in generator systems can be particularly difficult to detect, as the current does not always have a clear return path. Furthermore, not all ground faults can be easily detected using conventional overcurrent protection methods.

Ground faults in a generator system may not result in currents high enough to trigger conventional overcurrent protection, especially in the case of high impedance faults. This can leave the generator vulnerable to prolonged damage.

0 notes